Build smarter

Modern construction

challenges require modern approaches

What keeps you up at night? Making the right decisions to deliver

high-quality multi-residential

projects without compromising on budget? Tight schedules? A crippling staff shortage? All of the

above?

We can help.

Why work

with us

From the initial kick-off to the final quality checks at the hand-off, TMS experts support you at every stage of your project. We understand the pressure you’re under—and we find the pragmatic solutions to make it all happen. Our obsession for rigour is only matched by our renowned technical support and customer service.

The proof is in the numbers

25

years of

experience

300 000

sq. ft. plant

Capacity to produce

3000

units each year

97%

clients rely on us for other projects after their first experience

10

installation teams

TMS is the pioneer in complete prefabricated structures for multi-residential buildings. Their difference? They’re made with concrete and steel, combining the very best properties of both materials. With our turnkey solutions, you get the best of both worlds. And you never have to compromise.

Not convinced a prefabricated approach could work? Think the same ol’ same ol’ way of doing things can’t be improved—but can still meet modern demands?

Let’s show you why TMS is challenging the status quo—and why we are the cornerstone of contemporary multi-residential construction.

How it works

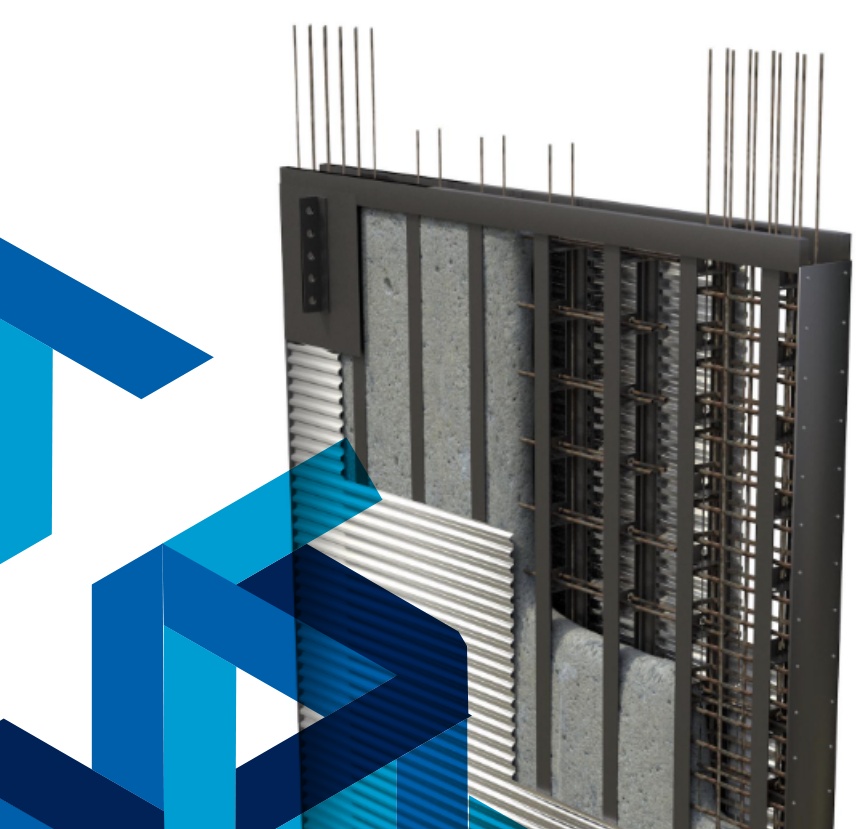

Based on the requirements of your multi-residential project, we combine exceptionally high-quality structures, including: panelized load-bearing steel stud walls, composite floor systems, permanent steel form for concrete shear walls, precast concrete balconies, pre-assembled stairs, structural steel, open web steel joists, and deck into one complete system that streamlines the construction process for contractors and developers.

Our prefabricated structures are made thanks to our 100% vertically integrated, in-house process, which means we have total control over the customized fabrication, craftsmanship, assembly and quality control. What’s more, nothing is left to chance. We respect and even exceed acoustic and fire protection standards to offer maximum comfort and protection to end users.

Even more impressive? Our team shows up on your worksite to erect the structures in no time flat. It’s like having many extra pairs of hands when you need them most.

Take a look at it for yourself:

Advantages

We go beyond the bottom-line price. There’s a lot of technical ingenuity and quality that goes into each of our complete prefabricated structures. And all that ingenuity and quality can lead to substantial savings. Do the math. You’ll notice the value TMS brings to the table.

Advantages of the design

- Lightweight structure for the ground

- No bulkheads

- Simple bracing system

- Sloped insulation not required on roof

- Reduced weight compared to cast-in-place

- Long-span joists

- Fire-tested assemblies

Advantages of prefabricated construction

- Turnkey structures

- Quality craftsmanship

- Easy assembly

- Little on-site labor required

Advantages at the worksite

- Speed and efficiency on site - Integrated coordination

- Parallel construction

- Minimal impact of winter conditions - Rapid

- Waterproofing of the envelope

- One concrete pour per floor (12 h cure)

- Simple safety

- Simple mechanical distribution

Advantages on user comfort

- Good soundproofing

- No sagging

- Building envelope with few thermal bridges